The Importance of Cleaning and Maintaining Your Fistreem Cyclon Water Still

High-purity distilled water is the backbone of countless laboratory workflows — from reagent preparation and media formulation to analytical applications where precision is essential. The Fistreem Cyclon water purification system is designed to deliver consistent, reliable distillate. But like any piece of laboratory equipment, its performance depends heavily on regular cleaning and maintenance.

Neglecting these simple routines doesn’t just impact water quality — it can shorten the lifespan of your system and compromise the accuracy of your work. In this guide, we’ll break down why cleaning is vital, how often it should be done, and what steps you can take to protect your still for the long term.

Why Regular Cleaning Matters

- Limescale and contaminant build up

Feedwater naturally contains minerals such as calcium and magnesium. As the Cyclon heats and boils this water, those minerals are left behind, gradually forming limescale inside the boiler and on heating elements. This buildup acts as an insulating layer, forcing the system to work harder to reach boiling temperature. Over time, it stresses internal components, increases energy consumption, and slows the distillation rate. Dried limescale build-up may contract over time, resulting in cracks in the glassware.

- Blocked Pipes and Drain Valves

Scale and residue can obstruct internal pipework and the drain valve. When this happens:

- The boiler may not empty completely

- Stagnant water can remain inside the system

- Flow rates may drop

- Water purity can be compromised

These small issues can escalate quickly, reducing overall performance.

- Reduced Efficiency = Higher Costs

Deposits on heating elements cause uneven heating and increase energy usage. Regular cleaning keeps the system operating efficiently and prevents unnecessary repair or replacement costs.

- Water Contamination Risks

Loose scale can flake off into the boiler and ultimately affect the purity of the distilled water — a serious issue for sensitive applications such as:

- Buffer and reagent preparation

- Tissue culture workflows

- Molecular biology assays

Maintaining the still is essential to maintaining the integrity of your research.

Figure 1- Fistreem system showing a significant build up of limescale

How to Clean Your Fistreem Cyclon: Step-by-Step

Please use the link below to download the step by step instructions.

Cleaning and Maintenance guide Cyclon systems

How Pretreatment Works

Pretreatment cartridges remove hardness ions from the feedwater before it enters the boiler, significantly reducing the formation of mineral deposits within the system. By limiting limescale build-up at the source, these cartridges help maintain consistent system performance and protect critical components.

The use of pretreatment cartridges offers several operational benefits. Reduced limescale accumulation improves energy efficiency by allowing heating elements to operate more effectively. This, in turn, helps extend the lifespan of both heating elements and glass components, reduces the frequency of manual cleaning, and lowers the risk of contaminants entering the distilled water.

To ensure continued effectiveness, pretreatment cartridges should be replaced at appropriate intervals. Replacement is recommended if a reduced water flow rate is observed, if there is a noticeable change in conductivity, or in accordance with the usage guidelines provided by your cartridge supplier.

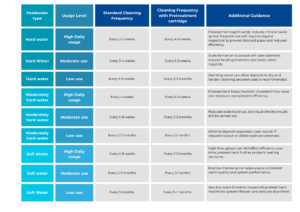

How Often Should You Clean Your System?

Footnote

Water hardness classifications are indicative and based on typical mineral content (primarily calcium and magnesium ions) in the feedwater supply. Local water quality can vary significantly, and laboratories are advised to consult local water hardness data where available.

Usage levels are defined as follows: high daily use refers to continuous operation or multiple distillation runs per day; moderate use refers to regular daily or near-daily operation with single runs; and low use refers to occasional operation, typically a few times per week or less.

Routine visual inspection of the boiler, heating elements, pipework, and drain valves is recommended. Cleaning should be carried out sooner than the suggested intervals if visible scale, reduced water flow, or decreased distillation efficiency is observed

Signs your Cyclon needs attention:

Addressing these signs early helps minimise downtime and maintain reliable distilled water output.

Conclusion: Protect Your Equipment — and Your Results

Routine cleaning and maintenance are essential for maintaining performance, protecting your equipment investment, and ensuring reliable, high-purity water for your laboratory applications. With simple, consistent care, your Fistreem Cyclon can deliver years of dependable operation.

Ready to keep your Fistreem Cyclon running at its best?

Whether you need pretreatment cartridges, descaling solutions, or guidance on setting up a maintenance schedule, our technical support team is here to help.

👉 Contact us today for personalised advice or to order maintenance supplies.