Vacuum Ovens Explained: The Science, Safety, and Selection Guide Every Researcher Should Know

Vacuum ovens have become essential tools in modern research and industrial laboratories. Whether used for drying heat-sensitive samples, removing solvents, degassing materials, or performing controlled thermal treatments, vacuum ovens enable precision and reproducibility that standard ovens cannot match.

This guide covers how vacuum ovens work, which industries rely on them, the safety advantages they offer, and what to consider when purchasing one.

What Is a Vacuum Oven?

A laboratory vacuum oven is a sealed heating chamber designed to operate under reduced pressure. By lowering the internal pressure, liquids boil at significantly lower temperatures, allowing researchers to dry samples gently and efficiently. This protects delicate materials from thermal degradation, oxidation, and contamination—making vacuum ovens crucial for research environments that demand precision.

How Vacuum Ovens Work?

Vacuum ovens operate by creating a reduced-pressure environment in which a vacuum pump removes air and gases from the chamber, lowering the boiling points of water and solvents so they evaporate rapidly at much lower, safer temperatures. Heat is applied uniformly through conductive shelves and well-insulated chambers, ensuring each sample experiences a consistent thermal profile. Advanced control systems—including digital or touchscreen interfaces, programmable temperature ramps, precise vacuum setpoints, real-time monitoring, and data logging—allow users to fine-tune both temperature and pressure conditions. Because the chamber is largely oxygen-free, oxidation is minimised, contamination is reduced, and sensitive materials remain more stable throughout the drying process.

Key Applications and Industries Using Vacuum Ovens

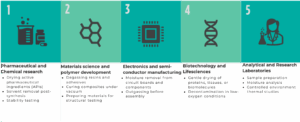

Vacuum ovens are used in a wide range of scientific and industrial fields, including:

Optimising Vacuum Oven Results Starts with the Right Pump

Selecting the right vacuum pump for your vacuum oven is crucial for achieving efficient drying, reliable solvent removal, and consistent results. A pump that matches the oven’s requirements helps maintain stable vacuum levels, shortens processing times, and prevents contamination—key factors for producing reproducible data in any research setting.

Two pump types commonly used with vacuum ovens are chemical-duty diaphragm pumps and filtration diaphragm pumps. Chemical-duty diaphragm pumps are designed to handle aggressive or high-vapour-load solvents, making them ideal for applications such as sample drying, concentration, and gentle solvent evaporation. Their chemically resistant materials and oil-free operation minimise maintenance and prevent back-streaming, ensuring a clean workflow. Filtration diaphragm pumps, while also oil-free and easy to maintain, provide lower vacuum levels and are better suited to tasks like vacuum filtration or basic aspiration rather than deep-drying applications.

For vacuum oven work, chemical-duty diaphragm pumps are typically the best fit. They provide the deeper vacuum and solvent-handling capability needed to efficiently dry sensitive samples without introducing contaminants. Choosing the correct pump not only optimises oven performance but also supports safer, cleaner, and more reliable operation in the laboratory.

Advantages of Using a Vacuum Oven

A laboratory vacuum oven provides the clear advantage of low temperature drying, as reducing the internal pressure allows moisture and solvents to evaporate at much gentler temperatures. This helps protect heat-sensitive or delicate materials from damage, ensuring that their structure and chemical properties remain intact throughout the process.

Another major advantage is the faster drying time achieved under vacuum. Because liquids evaporate more readily when pressure is reduced, samples dry more quickly and more evenly, improving efficiency and supporting higher throughput without sacrificing quality.

A further benefit lies in the oven’s ability to maintain a low-oxygen environment, resulting in reduced oxidation. Sensitive materials that might otherwise corrode, discolour, or react with air remain stable, which is particularly important in chemical, pharmaceutical, and materials research.

The vacuum environment also contributes to enhanced safety, as the limited presence of oxygen lowers the risk of combustion and reduces the accumulation of flammable vapours when removing solvents. This makes the process safer for both operators and samples.

Finally, the combination of controlled heat and stable vacuum conditions provides precise and reproducible results. Researchers can perform drying, curing, or degassing procedures with confidence, knowing that the conditions can be repeated reliably from one batch to the next.

Protecting Users and Samples with Essential Safety Features

When selecting a vacuum oven, safety should be a top priority, especially when working with heat, volatile solvents, and negative pressures that can place significant stress on the equipment. One of the most important protections is over-temperature safety, where automatic cut-offs prevent the chamber from exceeding safe limits and reduce the risk of thermal damage or runaway heating. High-quality vacuum ovens also use tempered or laminated glass in their viewing windows, allowing users to visually monitor samples without exposing themselves to the risk of breakage under vacuum conditions.

Equally important are pressure-release valves, which ensure the chamber can vent in a controlled manner and prevent sudden pressure changes that could compromise the oven or the samples inside. The overall construction of the chamber—typically heavy-gauge steel or aluminium—must be strong enough to withstand repeated cycles of vacuum and heat without warping or failing. Modern ovens often include integrated alarms that alert users to deviations in temperature or vacuum levels, helping catch issues early and maintain stable processing conditions. Together, these features not only protect operators but also help preserve sample integrity and extend the lifespan of the equipment.

As modern research increasingly relies on reproducible data, precise control of temperature, pressure, and timing has become essential. Today’s vacuum ovens often include programmable profiles, real-time monitoring, stable vacuum setpoints, and data logging to support method development and traceability. These capabilities allow researchers to maintain consistent processing conditions, compare results across experiments, and protect sensitive materials from variation.

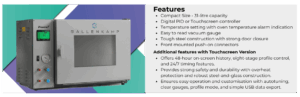

With this growing emphasis on precision, many laboratories look for vacuum ovens designed with stable control systems and robust construction that support reliable day-to-day use. The Gallenkamp vacuum ovens supplied by Synoptics follow this design philosophy. They focus on delivering consistent temperature uniformity, dependable vacuum performance, and clear operator control—features that align well with the practical needs of research and industrial facilities.

Vacuum Oven Buying Guide: How to Choose the Right Model

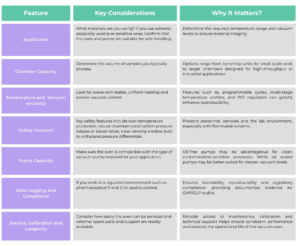

Selecting the right vacuum oven depends on your specific research needs and the conditions under which your samples will be processed. The following considerations can help guide your decision:

Conclusion

Vacuum ovens are indispensable tools for any laboratory requiring safe, precise, and repeatable drying or thermal processing. Their ability to operate at low temperatures under reduced pressure makes them ideal for sensitive materials used in pharmaceuticals, electronics, materials science, and biotechnology.

If your workflow depends on precision and reproducibility, the right vacuum oven makes all the difference.

If you would like to explore our range, head over to the website: https://www.synoptics.co.uk/product-category/gallenkamp/

Speak with our experts at Synoptics Ltd to find the ideal Vacuum oven model for your research needs.